The drive shaft assembly is composed of a shaft tube, a telescopic sleeve and a universal joint. The telescopic sleeve can automatically adjust the distance between the transmission and the drive shaft. The universal joint is to ensure the change of the angle between the output shaft of the transmission and the input shaft of the drive axle, and realize the constant angular speed transmission of the two shafts.

Universal joint

Universal joint is a key component of automobile drive shaft. A car is a moving object. In a rear-drive car, the engine, clutch, and transmission are installed on the frame as a whole, and the drive axle is connected to the frame through an elastic suspension. There is a distance between the two and needs to be connected. When a car is driving, uneven roads can cause jumps.

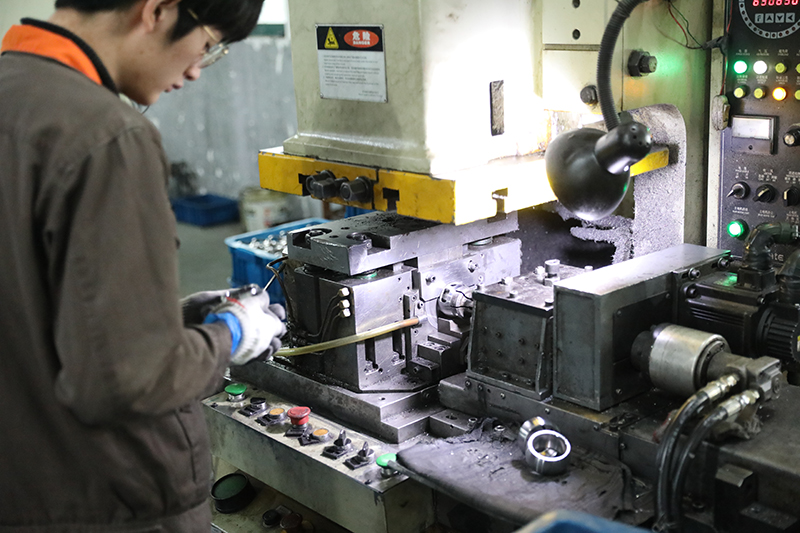

The universal universal joint is composed of a cross shaft, a cross bearing and a flange fork. Universal joint is a key component of automobile drive shaft. On vehicles equipped with front engine and rear-wheel drive, the universal joint drive shaft is installed between the transmission output shaft and the drive axle final drive input shaft. On the other hand, a front-wheel drive vehicle with a front engine omits the transmission shaft, and a universal joint is installed between the front axle half shaft and the wheels, which are responsible for driving and steering.

Telescopic sleeve

The traditional structure of the transmission shaft telescopic sleeve is to weld the spline sleeve and the flange fork together, and weld the spline shaft to the transmission shaft tube. The new drive shaft has changed the traditional structure. The spline sleeve and the drive shaft tube are welded together, and the drive shaft integrates the spline shaft and the flange fork into one. The rectangular tooth spline is changed to a large pressure angle involute short tooth spline, which not only increases the strength, but also facilitates extrusion forming to meet the needs of high torque working conditions. On the tooth surface of the telescopic sleeve and the spline shaft, a layer of nylon material is coated and impregnated as a whole, which not only increases the wear resistance and self-lubrication, but also reduces the damage of the impact load to the drive shaft and improves the cushioning capacity.